Sustainability

Lifecycle of a Product

- Combining films and foils (polymers, paper and aluminium) to benefit from the cumulated material properties.

- Customisable barriers and other functionalities (e.g. printability, sealing)."

- Lightweight and low volume reduces energy used for transport and storage.

- Outstanding low packaging-to-product ratio (5 to 10 times lower than alternatives).

- Reduced use of materials and energy throughout supply chain resulting in reduced environmental footprint.

- Sizes, formats and shapes can be easily and quickly adjusted.

- Keeps good things in and bad things out - essential for food, pharmaceuticals and beverages.

- Customised barriers and protection by smart combinations of different materials.

- Optimising shelf life for a variety of perishable goods.

- Can also allow some products to breathe or maintain modified atmospheres for long periods.

- Much less material used for the same purpose.

- Flexible Packaging packs half of food products in Europe while only using one sixth of all consumer packaging materials.

- Much less material in packaging waste stream.

- Very low packaging-to-product ratio: 5 to 10 times lower than alternative solutions.

- Variable pack sizes to fit product – not one size fits all.

- Shape and format can be adjusted to exactly fit product volume - not one size fits all.

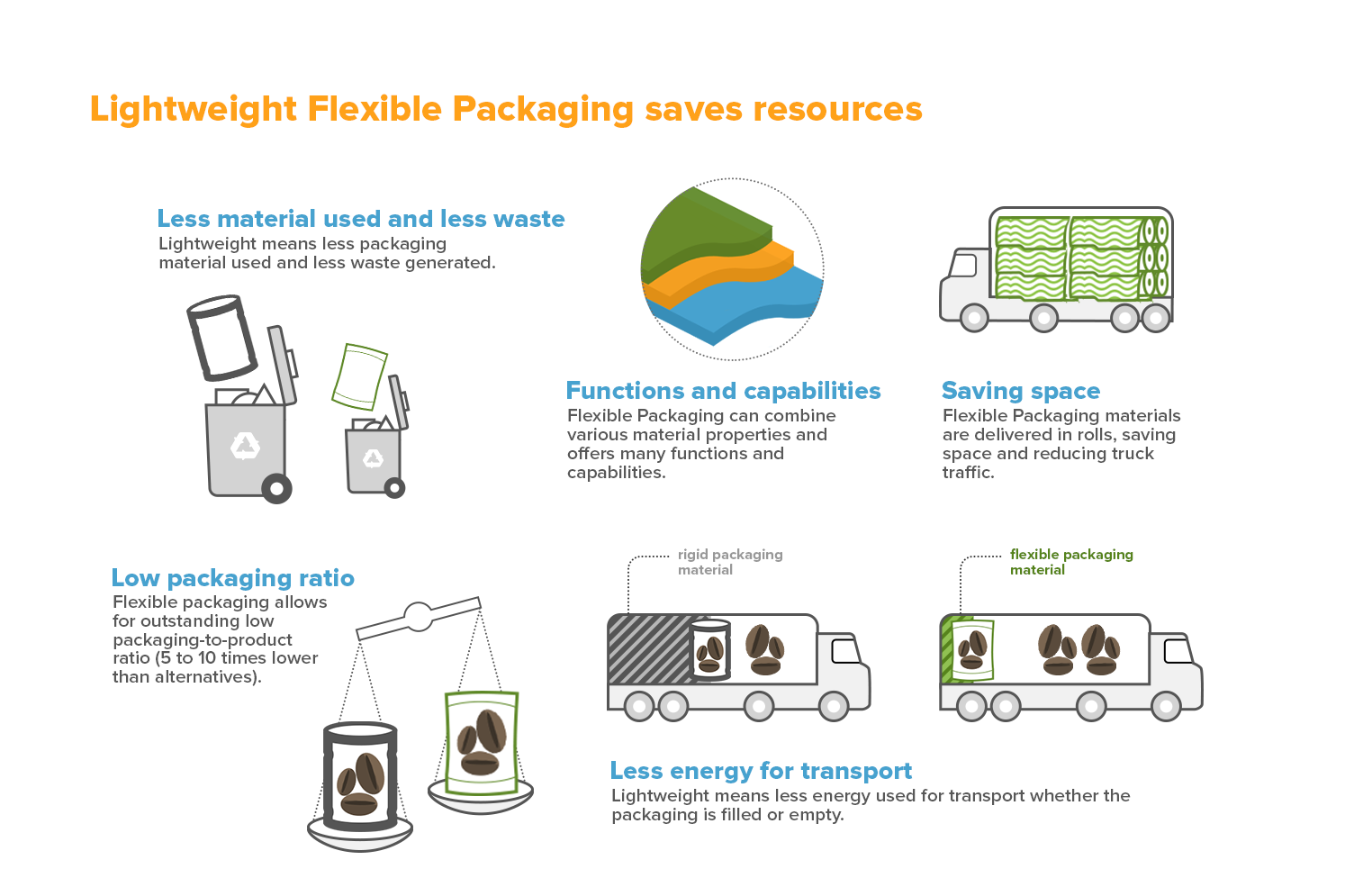

- Lightweight means less packaging material used and less waste generated.

- Flexible Packaging can combine various material properties and offers many functions and capabilities.

- Flexible packaging allows for outstanding low packaging-to-product ratio: 5 to 10 times lower than alternative solutions.

- Lightweight means less energy used for transport – whether the packaging is filled or empty.

- Flexible Packaging has a very low packaging-to-product ratio: 5 to 10 times lower than alternatives.

- Packing all food in rigid materials would require an additional 23 million tonnes of packaging materials in the EU.

- Packing all food in Flexible Packaging would save 26 million tonnes of packaging materials in the EU.

- Packing all food in Flexible Packaging, even with 0% recycling, would reduce the total carbon footprint for packaging by 40% in the EU (≈1% of all EU greenhouse emissions).

- Packing all food in rigid materials, even with 100% recycling rate, would increase the total carbon footprint for packaging by 6% in the EU.

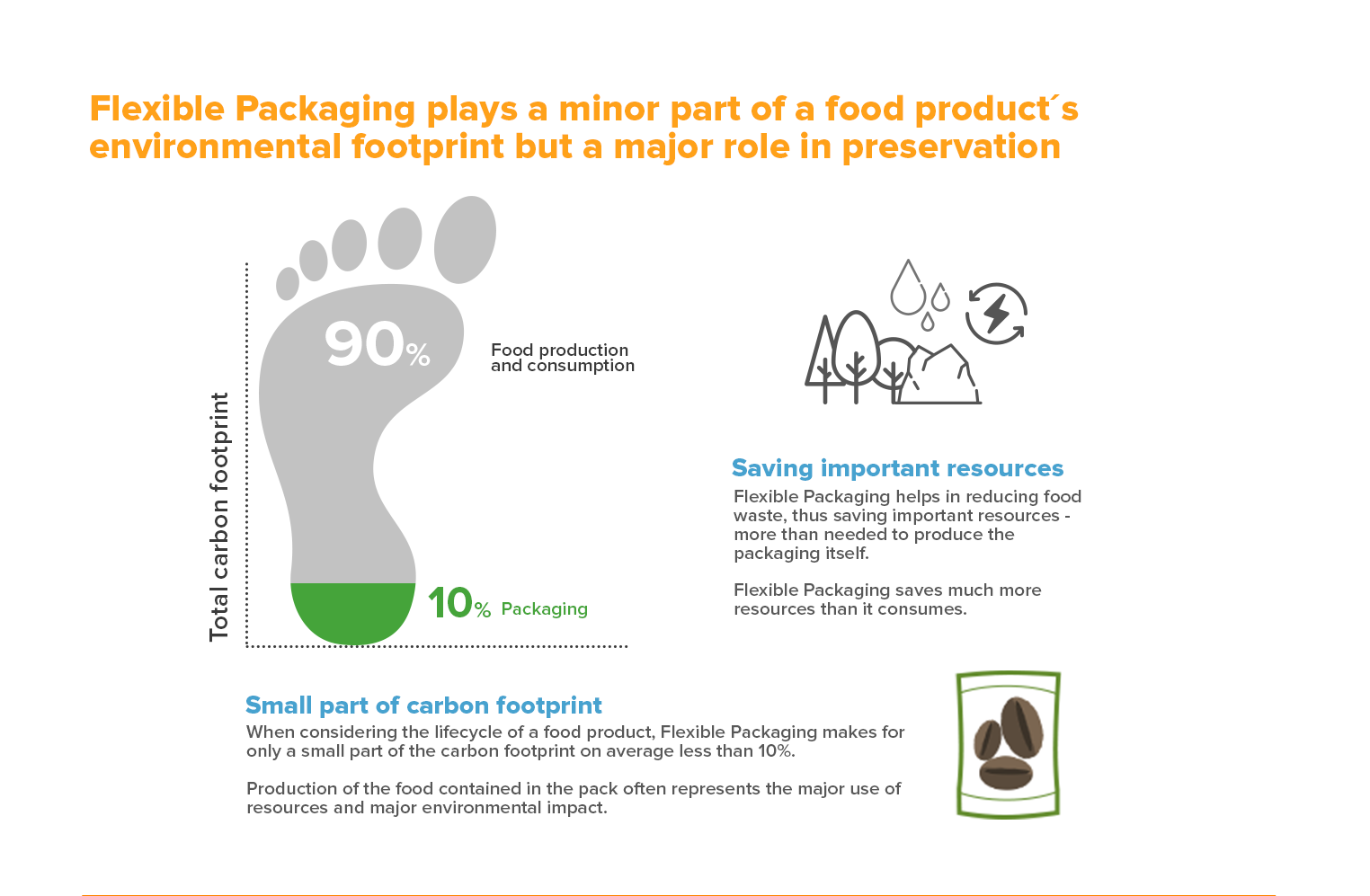

- When considering the lifecycle of a food product, Flexible Packaging makes for only a small part of the carbon footprint – on average less than 10%.

- Production of food inside the pack often represents the major use of resources and major environmental impact.

- Flexible Packaging helps in reducing food waste, thus saving important resources - more than needed to produce the packaging itself.

- Flexible Packaging saves much more resources than it consumes.

- Serving same purpose while consuming much less material and energy resources throughout entire lifecycle.

- Less material used results in less packaging waste to collect, sort and recycle.

- Even with low recycling rates Flexible Packaging often generates less material losses than alternatives. Nevertheless, the objective is to maximize collection, sorting & recycling.

- A 50g rigid pack with a 80% recycling rate results in 10g material loss while an equivalent 5g flexible pack with a 0% recycling rate results in only 5g material loss.

- Flexible Packaging is an essential part of the food chain.

- It helps to contain and preserve food throughout the chain and enables proper and safe delivery to the consumer.

- Flexible Packaging is part of the solution to prevent food waste which is a major environmental and economic problem globally.

- Flexible Packaging is generally more resource efficient than alternative solutions due to its very light weight.

- 1/3 of food produced globally is never eaten – representing a major wastage of resources (e.g. water, energy, land) and unnecessary greenhouse gas emissions.

- Flexible Packaging provides solutions thanks to customizable design for appropriate preservation and serving formats.

- Adjustable portions and formats reduce potential leftovers on the plate and in the pack.

- Offers extended shelf-life and storage options for a wide range of foods (e.g. meat, dairy, coffee, vegetables), thus reducing food waste at the retail and consumer level.

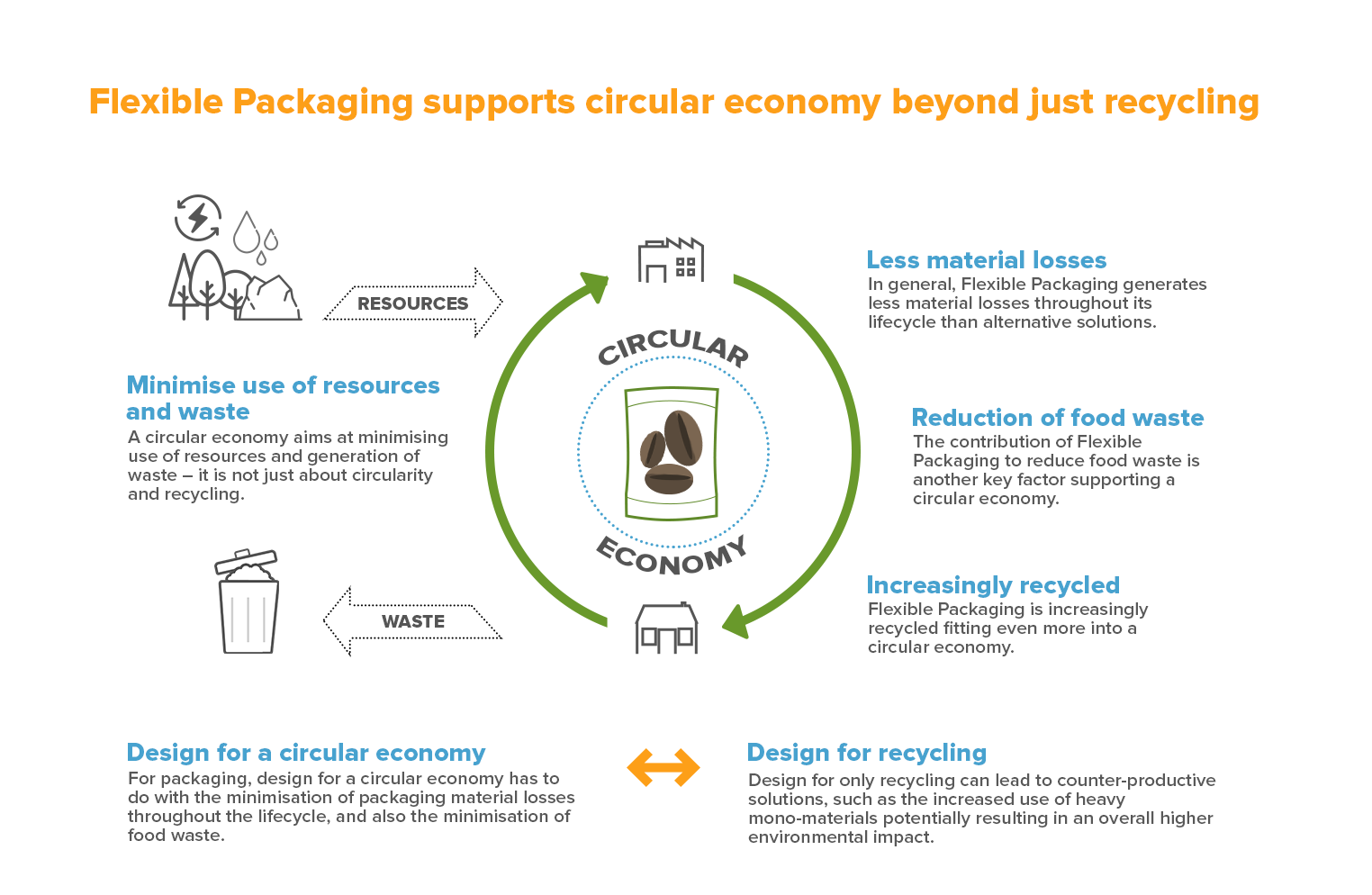

- A circular economy aims at minimizing use of resources and generation of waste – it is not just about circularity and recycling.

- For packaging, design for a circular economy has to do with the minimization of packaging material losses throughout the lifecycle, and also the minimization of food waste.

- Design for only recycling can lead to counter-productive solutions, such as the increased use of heavy mono-materials potentially resulting in an overall higher environmental impact.

- In general, Flexible Packaging generates less material losses throughout ist lifecycle than alternative alternative solutions.

- The contribution of Flexible Packaging to reduce food waste is another key factor supporting a circular economy.

- Flexible Packaging is increasingly recycled fitting even more into a circular economy.

- Proper collection at all levels is required for successful recycling.

- Collection prevents packaging from leaking into the environment.

- To avoid cherry-picking of easy recyclables, mandatory separate collection of all packaging is needed.

- Without mandatory collection, Flexible Packaging may not generate sufficient material volumes to make recycling commercially viable.

- Mandatory collection is the basis for more investment in infrastructure for sorting and recycling of Flexible Packaging.

- A very small part of Flexible Packaging used in Europe is being littered.

Less than 0.1% ends up as marine litter.

This issue has to be tackled. - Waste management systems in Europe need to be optimized – starting with better collection.

- Proper collection of all Flexible Packaging will prevent them from leaking into the environment and improve recycling.

- Marine litter is a global issue with Europe representing only a small part of it. Adequate waste management is needed everywhere.

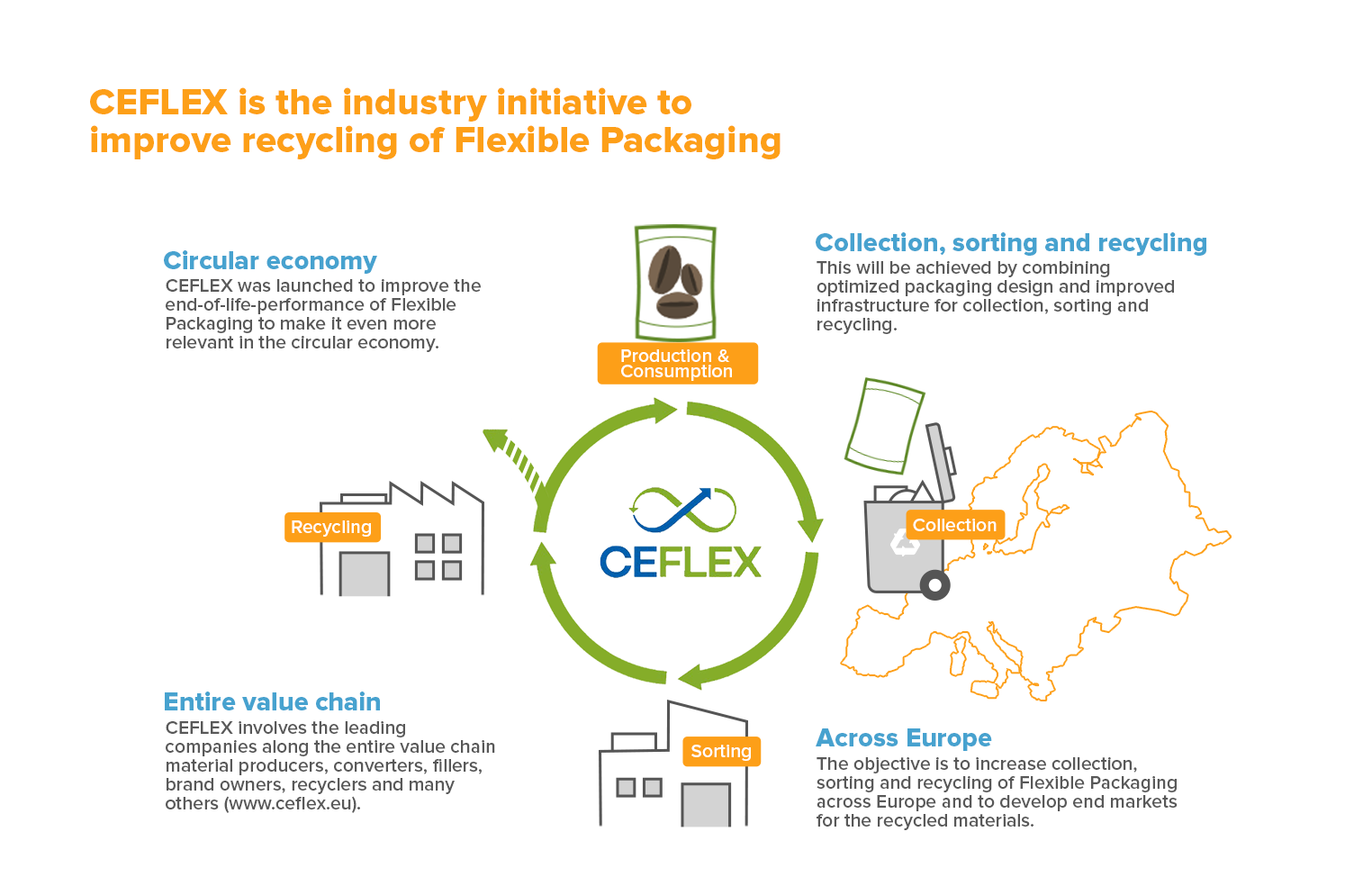

- CEFLEX was launched to improve the end-of-life-performance of Flexible Packaging to make it even more relevant in the circular economy.

- CEFLEX involves the leading companies along the entire value chain: material producers, converters, fillers, brand owners, recyclers and many others (www.ceflex.eu).

- This will be achieved by combining optimised packaging design and improved infrastructure for collection, sorting and recycling.

- The objective is to increase collection, sorting and recycling of Flexible Packaging across Europe and to develop end markets for the recycled materials.

- Flexible Packaging is not yet widely recycled. The very small amount of material contained in Flexible Packaging is generally more challenging to recycle economically than rigid mono-materials.

- Key stakeholders of the entire Flexible Packaging value chain initiated the CEFLEX project to improve sorting, recovery and recycling.

- Energy recovery is a viable alternative for non-recycled materials.

- No successful recycling without proper collection.

- Continuous improvemnent of collection, separation and recycling technologies will increase the recycling rates of flexible materials.

- Among the recycling technologies already in use are mechanical recycling for mono and mixed (PO) plastics and pyrolysis for laminates with aluminium foil.