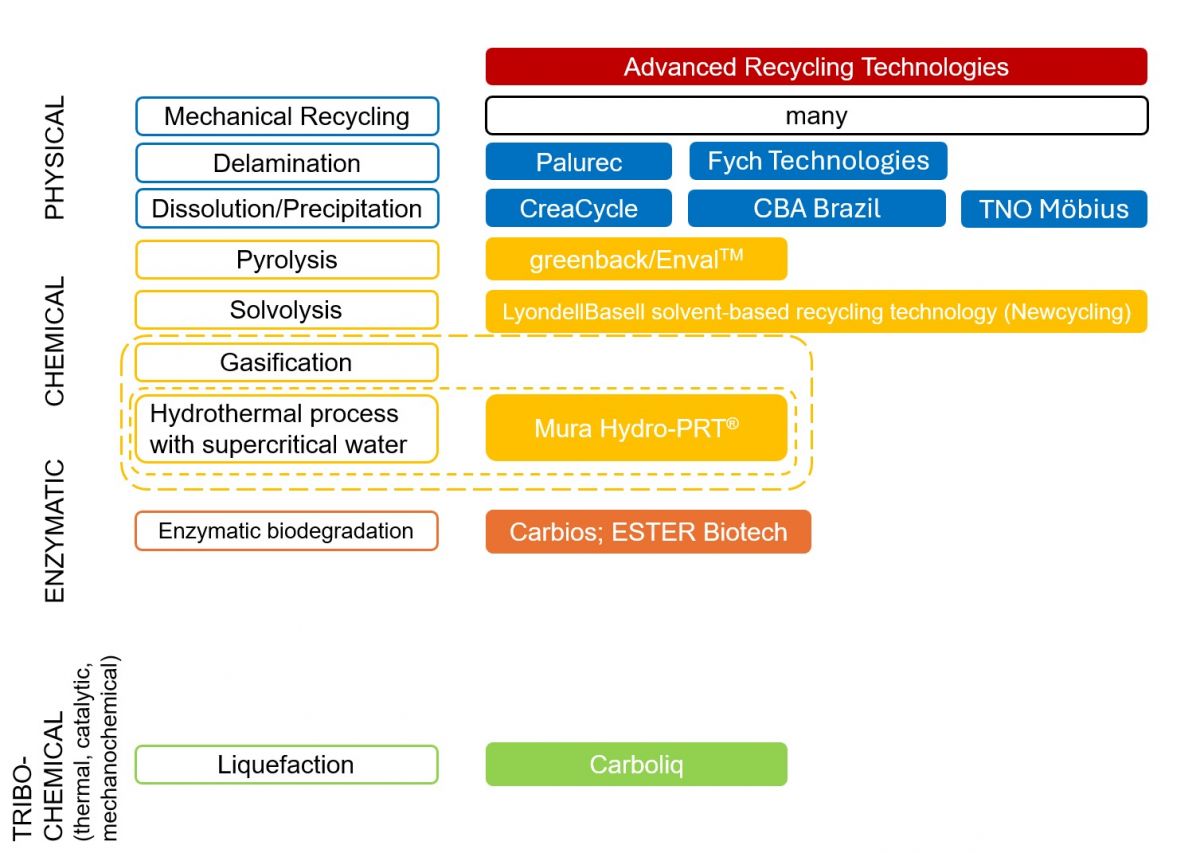

Mechanical recycling is a physical way to recycle materials. For plastic materials, this means that used plastic items (e.g. packaging which is collected in a separate stream) are transformed into recycled material that can replace virgin input material. Mechanical recycling processes do not break down the polymeric chains of plastic materials into monomers.

Typical process steps:

- Sorting (by polymer type and color)

- Shredding / grinding into flakes

- Washing & drying (removing content residues, labels, dirt, adhesives)

- Melting & reprocessing (extrusion, including melt filtration in order to remove remaining impurities), including “decontamination” & deodorization (removing, e.g., Volatile Organic Compounds [VOCs]

- Granulation

Mechanically recycled material is only legitimate to be used in contact with food, when the input material is collected in dedicated streams and under strict legal prescriptions. One example is the closed loop for PET beverage bottles under the German deposit-return scheme (DRS).

Delamination is a debonding of tie layers in multilayer materials by physical means with the aim of recovering and recycling the single layers (e.g., aluminium and PE) individually.

Typical approach:

- Specific input material is preferred (e.g., defibered beverage cartons)

- Shredding / grinding of the input material into flakes

- Adding a tailored delamination fluid and separation of the different layers under application of heat and mechanical action

- Density sorting

- Melting & reprocessing (extrusion, including melt filtration in order to remove remaining impurities)

- Granulation

Special “debonding-demand-adhesives” facilitate the targeted debonding of multilayer materials.

- Is applied to targeted input material

- Shredding

- Dissolution by tailored fluids

- Cleaning - insoluble impurities are separated

- The impurities can either be recycled (e.g., in the case of aluminium) or they will be sent to disposal.

- Recovery of the target polymer by precipitation

- Drying of the recovered polymer

- Extrusion / granulation

By chemical recycling, plastic polymers are broken down into monomers or into basic chemical feedstocks (oil/gas-like), which can then be used to make new plastics or chemicals.

Chemical recycling can take more challenging-to-recycle input material, which is hard to tackle by mechanical recycling.

Pyrolysis is a thermal process in which organic materials such as plastic waste is heated to high temperatures under the absence of oxygen in a reactor.

Input material: Mixed flexible plastic packaging & multilayer laminates, also containing aluminium

Main outputs:

- Pyrolysis oil (liquid hydrocarbon mix, which can be further processed and then used as chemical feedstock

- Pyrolysis gas (often used as input fuel to run the process)

- Solid char/residue

Advantages:

- Pyrolysis is useful for plastic waste which is challenging to recycle mechanically.

By solvolysis, a polymer is broken down by reacting it with a solvent (often with heat and a catalyst) to produce smaller molecules that can be purified and used to make new materials.

Common types (by solvent):

- Hydrolysis (water)

- Alcoholysis (alcohol)

- Glycolysis (glycols)

- Methanolysis (methanol)

- Enzymolysis / Enzymatic hydrolysis (enzymes)

- Aminolysis (amines)

Typical use:

- Works well for condensation polymers like PET and polyamides, turning them back into monomers or oligomers for re-polymerization.

Gasification is a high-temperature thermochemical process, by which the input material (e.g., mixed plastics material) is depolymerized into smaller molecules under the influence of heat and agents like oxygen or steam. The main outputs of this process are synthesis gas, a mix of carbon oxide, hydrogen, and light hydrocarbons.

By the Hydro-PRT® process, post-consumer plastic waste – including multi-layered flexible packaging – can be turned into circular hydrocarbon feedstocks.

Main process steps:

- Shredding

- Removal of non-plastic items from the stream

- Melting & Pressurization in an extruder

- Processing in a reactor with supercritical water

- Distillation to retrieve hydrocarbon feedstock

PLA degrading enzymes can be included in the PLA polymers and will be activated when the polymeric item is put on the compost.

In tribochemical processes, surfaces of the processed materials are mechanically activated, e.g. by friction, which triggers chemical reactions.

Liquefaction means the transformation of solid input material into liquid output material. It can be used as a low-temperature cracking of plastic polymers under the impact of a catalytic material which is tailored to the input material.

The Carboliq technology comprises a low-temperature tribochemical process by which plastic waste is turned into hydrocarbon feedstock. The process can also be categorized as direct oiling.

Main process steps:

- Pre-processing: Separation of ferrous and non-ferrous metals; homogenization & drying

- Reaction

- Condensation

- Liquid/liquid separation

When processing plastic waste containing PA6, the by-product caprolactam can also be recovered directly.